Request In-house Training Proposal

Please fill in the below form to receive our Latest Offers/Discounts for Individuals.

Why Attend This Training Course?

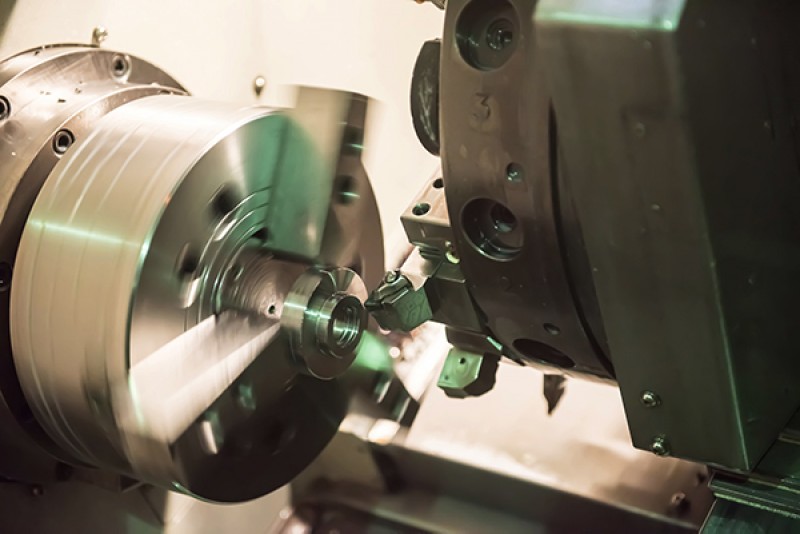

Solve the machinery failure problems costing you time and money with this classic, comprehensive guide to analysis and troubleshooting through a systematic approach to fault diagnosis and failure prevention in a broad range of machinery Participants will analyze a system’s failure modes and define how to prevent or find those failures early, learn techniques, tools and the procedures of root cause failure analysis and failure mode effective analysis as a proactive strategy for achieving precise operation and improving machinery performance. The key methods of preventive maintenance are demonstrated through the study of examples and a progressive approach to machinery troubleshooting and problem solving. Case studies will provide a forum for problem formulation, investigation and resolution.

What Is The Training Course Methodology?

This training methodology illustrates the concepts involved in the above areas through practical consideration of actual real-life problems, as well as explanation of concepts by experts in area using video projectors and computer aided case studies based on practical applications. Participants will solve their system problem, where the trainee’s try to apply the skills learnt with guidance from our specialized experts. ACAD will provide participants a comprehensive assessment on the problems solved using the skills acquired in the training course.

Who Should Attend This Training Course?

This training course is designed for Engineers and Technicians who are involved in vibration measurement and analysis, so that they may be fully involved in obtaining the maximum benefit from the implementation of the predictive maintenance system.

What Are The Training Course Objectives?

This course gives a thorough overview for experienced engineers, new engineers to familiarize them quickly in the rotating equipment field. It also gives basic principles of failure causes and diagnosis to develop participant’s skills of problem solving and failure reporting.

What Is The Training Course Curriculum?

Failure Analysis and Troubleshooting System

Causes of machinery failure

Machinery design properties

Metallurgical failure

Bolted joint failures

Shaft failures

Wear-related failures

Rolling element-bearing failure

Journal and Tilt-pad Thrust Bearings

Ring failure

Gear failure

Coupling failure

Mechanical seal failures

Mechanical seal selection

Lubrication of pump reliability improvement

Machinery Reliability Audits and Reviews

Machinery troubleshooting

Problem solving sequence

Failure reporting

Cases study

Failure reduction programs

Apply now

Search in Courses

Register Upcoming Courses

Training Categories

- Leadership, Strategy and Management

- Human Resources and Training

- Accounting and Finance

- Public Relations and Office Management

- Marketing and Sales

- Supply Chain and Logistics

- Health, Safety and Security Management

- Contracts Management and Legal Skills

- Interpersonal Skills and Self-Development

- Project Management

- Information Technology

- Mechanical Engineering

- Electrical and Electronic Engineering

- Industrial and Production Engineering

- Oil, Gas and Petroleum Engineering

- Civil and Construction Engineering

21 - 25 Jan

21 - 25 Jan Cairo, Egypt

Cairo, Egypt $1500

$1500