Choose your preferred training format and enroll today with ACAD Training & Consulting

Venues

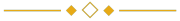

10+

Trainers

200+

Clients

5000+

Training Categories

20+

Participants

600,000+

Performed Courses

25,000+

The Right Step for Human Investment

Since competition has emerged as a fundamental reality that leads to either success or failure of businesses, the comprehensive change has become imperative. In so doing, a scientific approach that is able to manage and make the change happen effectively, starting with proper planning, creating the base of continuous change and defining goals objectively. To that end, specific resources have to be allocated to maintain the competitive edge of businesses. In addition, the entire process requires a management that has a macro vision for change at all organizational levels. An integrated approach to manage change is a pre-requisite together with professional, enthusiastic and supportive leadership. To contribute to these changing realities and to cope with the development of management and technical competencies that enable businesses lead the change and to apply integrated and continuous development approach to their human capital from a new perspective that is able to mitigate risks that are likely to impact business results. ACAD Training & Consulting has accomplished its’ training plan for the year 2025. The topics of the plan are unique and diversified in terms of certified and accredited training programs that meet the new realities and practices. Remain hopeful of satisfying your training needs.

Consultant Engineer Mohamed Ibrahim Saad

President of Arab Consulting And Development Corp. (ACAD Training & Consulting)

Upcoming Training Programs

Categories

International & Local Affiliations

Why do individuals seek Professional Certificates nowadays?

The swift evolution of the economy, propelled by technological advancements, has prompted employers to value employees who have enhanced their qualifications through the acquisition of advanced certificates or certifications relevant to their professions. This dedication to continuous skill development enables organizations to address the increasing demand for new competencies within the labor market.

The findings of the report indicated that individuals who obtained a certificate or certification experienced a heightened value in the job market regarding their educational qualifications. This trend was particularly pronounced among those lacking a college degree, as 60% of the nearly 50,000 working adults surveyed regarded their educational experiences as beneficial, in contrast to only 44% of respondents who did not possess any form of certification.

View all accredited courses

Venues

Testimonials

The course training expert 'Prof. Raouf Nassif' is an excellent trainer and very expert in his field, who present a magnificant amount of information, data, & expertise. Also, the course coordinator of ACAD Corp. is really professional & cooperative person. Thanks a million to 'Mr. Sherif Saad' for his great support.

Maintenance & Operation of Rotating Machinery

Orascom Construction - Egypt

Perfect Instructor, perfect & friendly organization, from CEO to buffet guy, who are working with passion, loving their work. I'll come again for new courses for sure :)

PMP Preparation Course

Enppi - Engineering For The Petroleum & Process Industries - Egypt

السادة / المؤسسة العربية للإستشارات والتنمية (أكاد) المحترمين، أسعدنى كثيرا مشاركتى وحضورى فى احد البرامج التدريبية المنفذة من قبلكم فى برنامج (مهارات التخطيط والتنسيق والمتابعة) والذى أستفدت منه الكثير على يد الأستاذ الدكتور الفاضل / أسامه فريد حفظه الله. مع خالص التحية والتقدير.

مهارات التخطيط والتنسيق والمتابعة

رئيس المرافق المؤجرة، مطار الملك خالد الدولى

الهيئة العامة للطيران المدنى

المملكة العربية السعودية

I would like to thank ACAD Corp. and all its staff members for the marvelous efforts to reach such quality assured and competency-based training in the PR and media.

Contemporary Approaches to Public Relations & Objective Media

Save the Children Organization - Yemen

It was a great pleasure to have this rich course with respectable person like Mr. Mohamed Owais, as it was my first and not my last time to have another course in this reputable training centre. Many thanks to ACAD training coordinator.

Measuring & Maximizing The ROI on Training - HRCI Pre-Approved Training Course

El Sewedy Electric - Egypt

اتقدم بوافر الشكر والتقدير لمنسوبى (أكاد) وعلى رأس الجميع رئيس المؤسسة الأستاذ المهندس/ محمد سعد وجميع المنسوبين واخص ايضا الاستاذ فتحى حيث كانوا بمثابة الأخوة والأصدقاء واشاعوا جواً من الألفه والمحبة والجميع مما أشعرنا بإننا وسط أخواننا وأهلنا وجعل الرغبة لدينا فى الحضور والمشاركة بكل نشاط فى البرنامج ونشكر أيضا الأستاذ الدكتور/ عادل سعد الذى لم يبخل علينا فى أى معلومة فلهم منا جميعا الشكر والتقدير وندعو لهم بالتقدم والازدهار وإلى الأمام .أنشاء الله

إدارة الأداء والتخطيط للتنمية الوظيفية

مشرف التدريب بقطاع الجنوب، مطار ابها الاقليمى

المملكة العربية السعودية

It was a great pleasure having a training course in your center. The instructor was more than perfect in delivering information. Surely, I will come back again soon for more trainings.

Situational Leadership Strategies

Ministry of Transport - KSA

فى هذا الإيجاز اود أن اشكركم على كل ما بذلتموه وما تبذلونه من جهد فى تنمية الموارد البشرية وحسن التعامل والثقة مع المتدربين لديكم كما لايفوتنى أن اتمنى لكم المزيد من التقدم والفلاح.

مهارات القيادة الإبداعية وبناء فريق العمل

معهد الإدارة العامة

المملكة العربية السعودية

فى نهاية أيام الدورة المنعقدة فى المؤسسة العربية للإستشارات والتنمية (مؤسسة أكاد) نهنئ أنفسنا بإختيارتنا لهذه المؤسسة العلمية التى تملك خيره النخبة العلمية القادرة على تقديم أفض المواد العلمية، كما لايفوتنى ان اشكر إدارة المؤسسة على حسن الاستقبال وكرم الضيافة متمنياً من الله ان تكون هناك علاقة على نطاق واسع مع الجمارك السعودية مع تحياتى وتقديرى لجميع أسرة المؤسسة العربية وكل عام وانتم بخير

النظم الإحصائية فى المحاسبة الحكومية طبقا لتصنيف صندوق النقد الدولى

مدير عام جمرك مطار الملك عبدالعزيز الدولى

مصلحة الجمارك – وزارة المالية

المملكة العربية السعودية

Our Clients

Enppi

View more

SAIB Bank

View more

Orascom Construction

View more

Banque Masr

View more

Juhayna

View more

Coca

View more

Ghabbour Auto

View more

Electrolux Egypt

View more

La Farge

View more

Bayer healthcare

View more

El Araby Group

View more

Nokia Egypt

View more

Sukari Gold Mines

View more

JICA

View more

USAID

View more

Yemen

View more

GIZ

View more

EL Sewedy Electric PSP

View more

Ezz Steel

View more

Dorra Group

View more

Saudi Aramco

View more

Hassan Allam Holding

View more

Japan Tobacco Industries - JTI

View more

mars wrigley

View more

El Ahly Sabbour

View more

NATCO S.A.E.

View more

SMG Engineering Automotive Company

View more

Aman - Raya

View more

Talaat Mostafa Group

View more

Lesaffre

View more

King's School - The Crown

View more

AMAN for Financial Services

View more

AKHNATON S.A.E

View more

Beltone Holding

View more

English/Arabic

English/Arabic 19 - 30 Jan

19 - 30 Jan $1800

$1800